Task Force Management

Methodology

The method of “task force management” originally comes from the US military and stands for the temporary combination of combat units. In business, it is understood to mean an interdisciplinary working group that is to solve a defined problem within a given time frame. By bundling competences and decoupling them from the organisation, faster results are delivered than with “organisation-standard” processes. The combination of professional competence (in terms of content as well as analytically/structurally), leadership quality (group dynamics of a temporary team) and decisiveness demand a lot from the leadership of a task force.

Starting Point

In a state-of-the-art, chain-linked production facility of a leading global supplier of engine and transmission components, typical start-up/initial problems could not be overcome : high scrap rates, low efficiency/OEE (Overall Equipment Efficiency), delivery backlogs and manufacturing cost problems.

A task force of internal and external experts was put together, which I was allowed to lead for one year. The very production-related topics required a high on-site presence (>90%) and thus offered optimal shop floor management conditions. A monthly status report was presented to the steering committee, where resources, budgets and directional issues were also discussed.

Project management & analysis

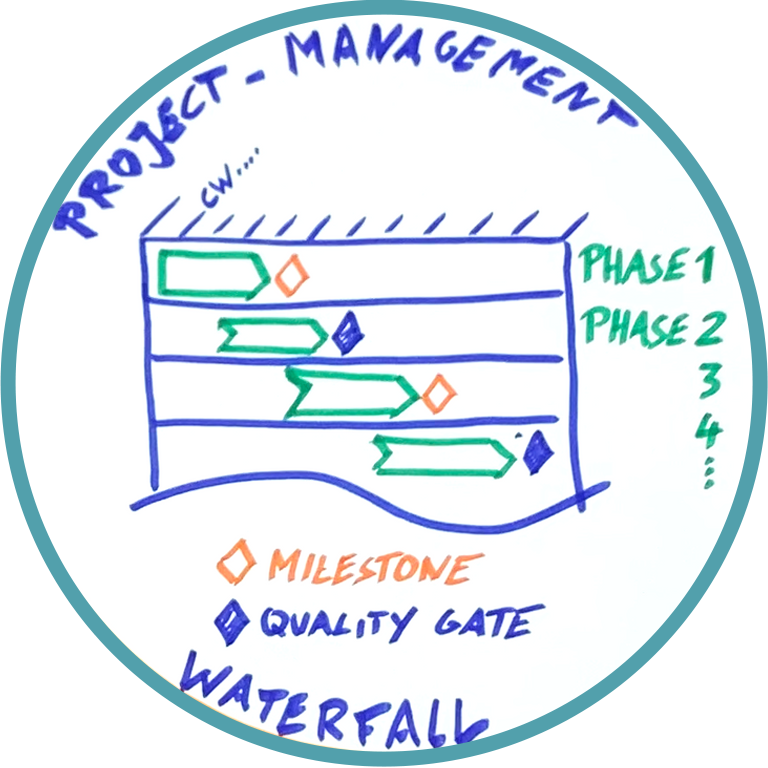

The project management was structured classically (waterfall), the project organisation and documentation was carried out in MS-TEAMS (with a differentiated authorisation structure for the internal and external experts as well as other stakeholders). Dailies” – later “weeklys” – ensured a consistent flow of information and coordination.

In an intensive analysis phase (including Ishikawa), possible connections between root cause and effect were searched in various categories (machine, material, human, etc.). An important task was the complete traceability of each produced component back to the basic material used (material/test certificates).

Evaluation & implementation

After evaluating the extensive analysis results, a bundle of measures was identified and prioritised in the team according to cost/benefit. In close coordination with the production planning/SCM, process optimisations were implemented during operation and numerous tests were carried out. Here are some examples :

- Optimisation of machining programmes and tools in the lathing process

- Processing trials with modified base material

- Optimisation of the cooling lubricant system (CLS) of the forming spinning process

- Trials with alternative lubricants

- Establishment of an electronic information board for the complete information of all employees in 3-shift operation (KPIs such as Q-rate, production requirement TARGET-ACTUAL, planned trials etc.)

Evidenced improvements (e.g. cleaning intervals of the CLS) were integrated into the process and implemented as a new standard (LEAN=>Avoid Wastage / PDCA).

Conclusion on the methodology

The method of “task force management” was ideally chosen for the above initial situation and thus the precondition for solving the complex task. The participants also gained a much deeper understanding of the entire process landscape – from purchasing over manufacturing to logistics/distribution.