LEAN Production

Background & core philosophy

In my function as technical manager of a medium-sized industrial company, I was responsible for the plant-wide introduction of a LEAN production/management system and took over the leadership and management of the project. Technical support was provided by the parent company and by an external management consultancy. A period of two years was planned (and needed) for the introduction of LEAN and its anchoring as a living corporate philosophy. LEAN also served as an accelerator in the transformation process from a (partly still existing) manufactory into a modern industrial factory/company.

The core philosophies were “production at the customer’s pace” and ” synchronised and low-waste production”. By means of clear targets/KPIs (productivity, quality costs, (current) stock, delivery reliability and employee satisfaction), the progress of the project was easily measurable and visible at all times.

Project management & preparation

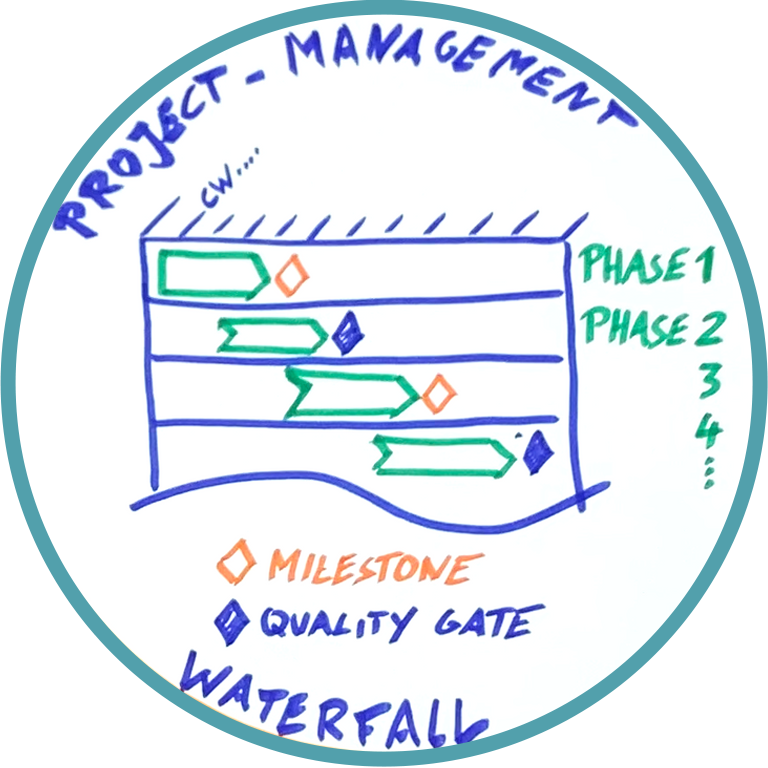

The formation of a core project team was followed by the establishment of a project structure with a project plan (classic) with sub-projects/work packages, cockpit (with traffic light status and degrees of hardness) and a filing structure for the complete project documentation.

The core team and other key employees (promoters) were intensively trained in LEAN basics and a LEAN reference manual with methods and tools was created. “Six Sigma Green Belts” were also trained and successfully deployed in the further course of the project.

The focus

In the LEAN focus areas (demand-oriented production / avoidance of waste / visualisation & standardisation / safe processes / promoting and challenging employees), a self-assessment (using a spider diagram) and at the same time an assessment by external experts was carried out. With the help of this internal and external perspective, focus areas and priorities could be derived, ranked and worked on.

Best practice & piloting

Regular visits to sister companies and LEAN benchmarks (e.g. Trumpf, Ditzingen or Roto Frank Dachsysteme, Bad Mergentheim) were important for a realistic self-assessment and also very motivating in the development of a vision/target. The strategy of introducing individual measures in “pilot departments” and the subsequent roll-out to the entire company was also an important success factor in the introduction of LEAN.

Continuous improvement

Following the LEAN introduction phase, a CIP system (Continuous Improvement Process) tailored to the company was developed and implemented in all departments (production/logistics & administration/sales). In the first two years, > 1000 CIP proposals were submitted and 85% of them were implemented.