LEAN Management

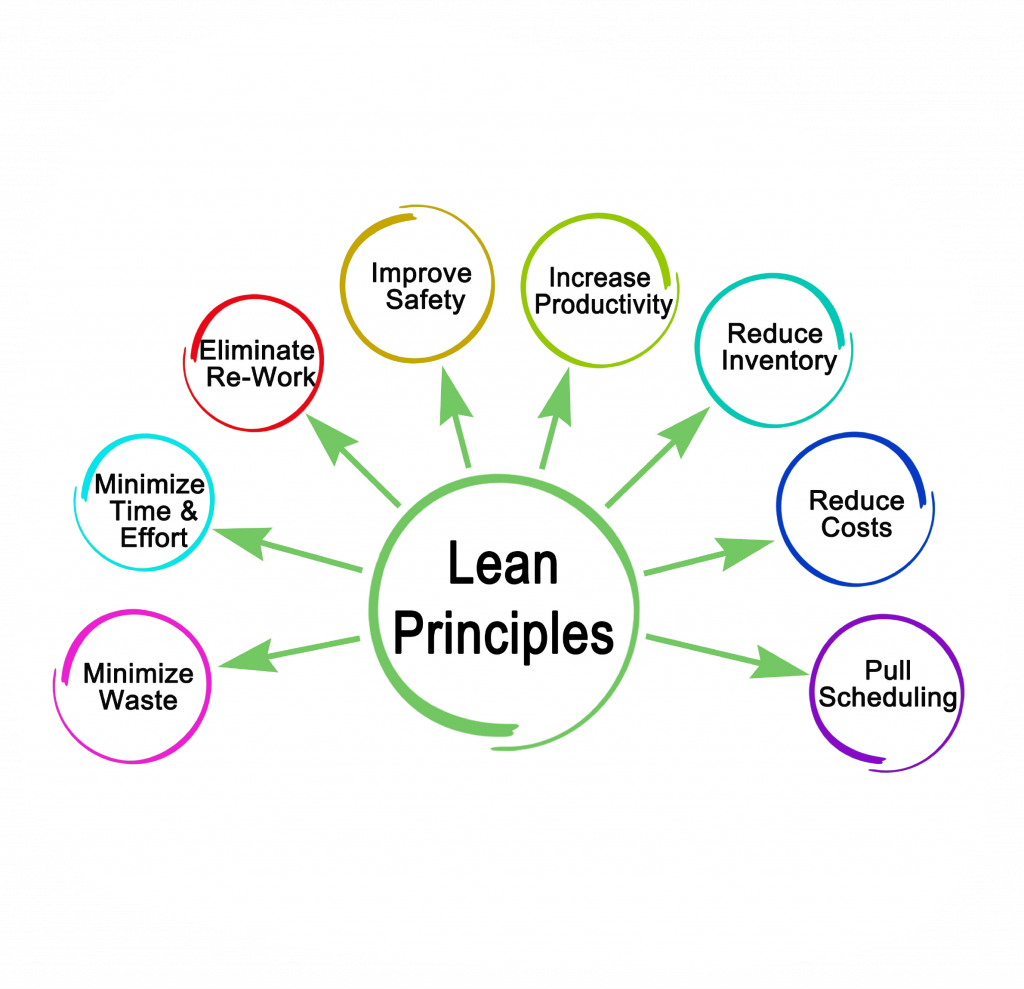

The core idea of LEAN is to “create value without waste”.

All activities that are necessary for the creation of value are to be optimally coordinated and unnecessary activities – waste – are to be avoided.

Customer orientation, process reliability, flow principle, avoiding waste, zero defects and a continuous improvement process are the principles for the improvement of the competitiveness of the value creation processes.

I am happy to support you in the introduction and implementation of LEAN.

A deep understanding of “lean thinking” is the fundamental precondition for a sustainable application of the LEAN principles. In training courses and workshops I can communicate/teach these basics to your management and employees.

Subsequently, basic knowledge of methods and tools should be trained (PDCA, Kaizen, 6S, 8V, VSA/VSD, Kanban etc.).

When planning the implementation of LEAN, the strategy of a selective introduction in a suitable “pilot department” and the subsequent “roll out” to the entire company has proved to work very successful.

LEAN is not to be understood as a project but as a corporate philosophy.

Not until a “continuous improvement process” has been implemented, LEAN is brought to life.

The active involvement of your employees in the LEAN activities and improvement processes plays a key role in the successful implementation of LEAN.

BTW…… “Lean Management” and “Agile Transformation” complement each other very well in practice.

Lean brings tangible improvements in value-adding processes, while agile methods improve efficiency and effectiveness in operational teamwork.