Backsourcing of a production to Germany

Starting point

A number of market factors, such as the shift towards a platform economy (=> declining retail trade), but also increasing competitive, price and margin pressure have led and continue to lead to massive sales and earnings problems for many german producers in the consumer goods sector. As a result, it is not uncommon for production (or parts of it) to be relocated abroad – often to China – and even in “make or buy” decisions, procurement has often been given priority over in-house production. The decreasing utilisation of in-house production then usually leads to an increased allocation of fixed costs => a vicious economic circle!

Quality problems in particular, but also poor availability, lack of flexibility and rising (procurement) costs are the key factors for a wave of relocations back to Germany (and EU).

Design for Manufacturing & Target Costing

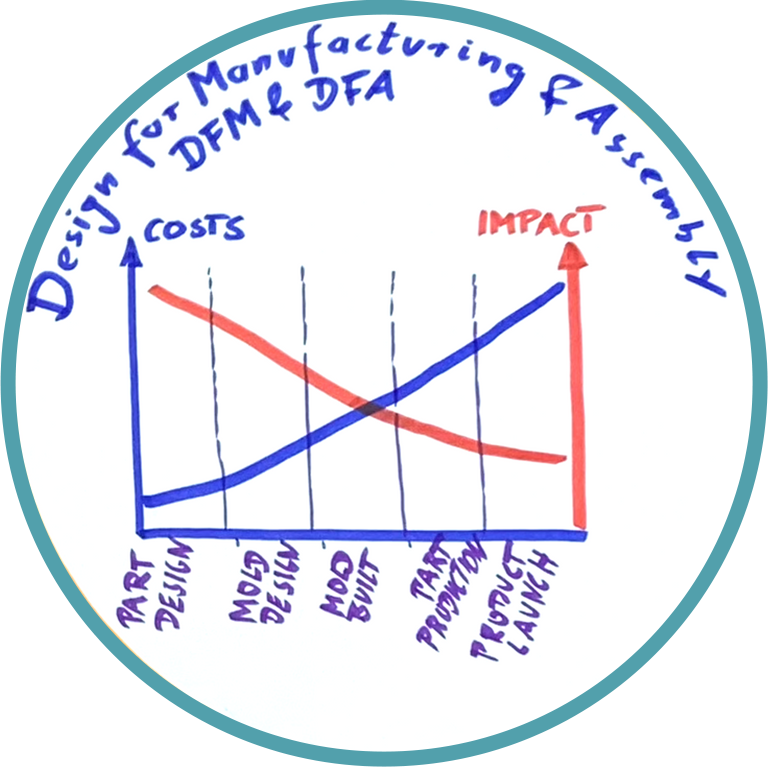

With the use of methods such as DFM and/or DFA (Design for Manufacturing/Assembly) as well as consistent “Target Costing”, a very successful “shift back” was achieved in the following example.

First of all, the question of what the manufacture of the product may cost was clarified in a market-oriented perspective (target costing). This led to a consistent and strict cost specification/orientation for the entire value chain.

The DFM/DFA methods were then used in product development, i.e. to focus on a product design that is good from a production point of view. Contracts with external designers were changed from “one-time-payment” to “royalties” to ensure maximum interest in economic success.

Lean processes

In order to achieve lean and low-waste production (LEAN), various existing production processes were questioned and investments made in “new” processes, e.g.

German suppliers were also integrated into the system of market-oriented cost accounting and contributed to the success of the “relocation”. By creating the major added value in Germany, the finished products could also be labelled “made in Germany” again – helpful for (inter)national sales.

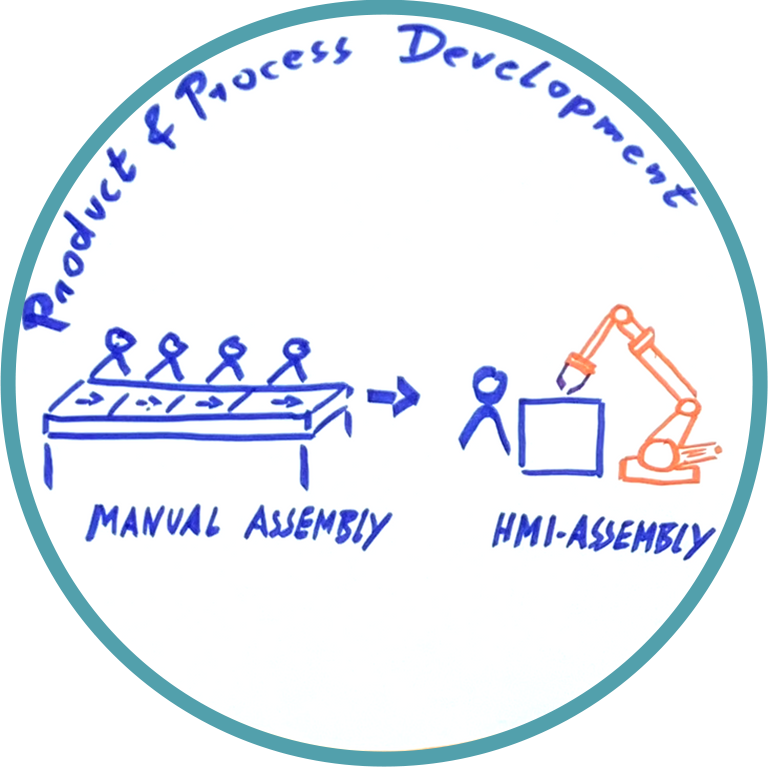

With a late variance point in production, a large assortment variety with high flexibility was ensured. The high labour cost share of assembly could be significantly reduced through flexible, partially automated assembly cells.

In my function as Technical Manager (with an affection for product development), I was able to play a decisive role in defining the product development process as well as process development and supplier integration. The entrepreneurs’ will to maintain and expand the production site in Germany was an integral precondition for this success story.