Improving economics –

a holistic approach

Task

An overall concept was to be developed for the subsidiary of a German group so that a sustainable operating result of 8% EBIT could be achieved on the basis of an existing product range and turnover level. For this purpose, various scenarios were to be identified and evaluated, while remaining flexible enough to allow future growth (without including this as a necessary success factor). In addition to alternative location concepts, synergy potentials within the group were also to be outlined.

Starting point

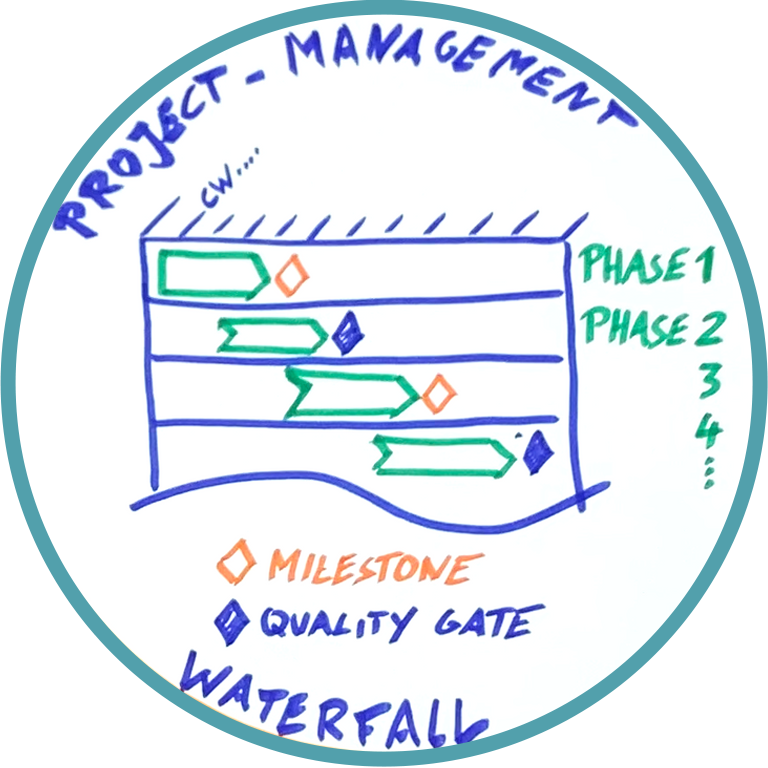

After setting up a project organisation consisting of a steering committee, project management and core team, various framework and boundary conditions were first analysed and documented. (Corporate strategy, competitive and market conditions, personnel, (fixed) costs, production technologies and capacities, investment planning, calculation bases, etc.).

Scenario development

The management team then developed different business model scenarios in workshops (from “optimisation of in-house production” to “100% external production”) and determined or estimated their costs and benefits (investments, cost, turnover and EBIT effects) as well as their implementation duration. The group’s board of directors decided on the scenario “optimisation of in-house production” and the resources required for this were approved in a modified business plan.

Content and implementation

As the company’s technical director, I was responsible for the project management and implementation of the selected scenario “optimisation of in-house production”. The sub-projects were diverse and numerous – e.g.:

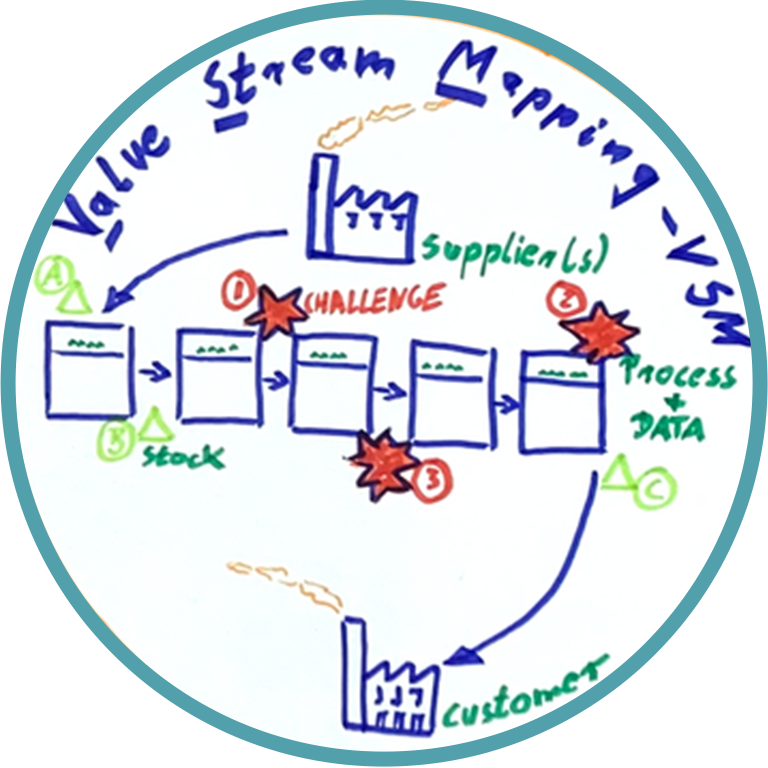

- Optimisation of material flow/value stream (plant structure planning with Fraunhofer IPA)

- Reduction of “complexity costs” (assortment adjustment, late variance points)

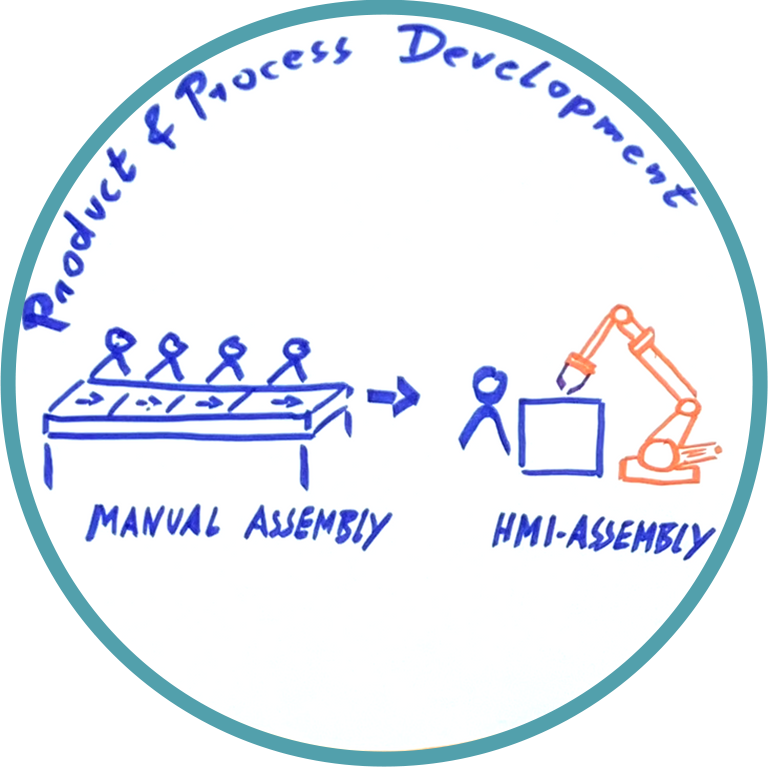

- Increasing the degree of automation (shaping, surface and assembly processes)

- Reduction of booking effort/expenses

- Components instead of individual parts procurement and outsourcing of costly “exotics”

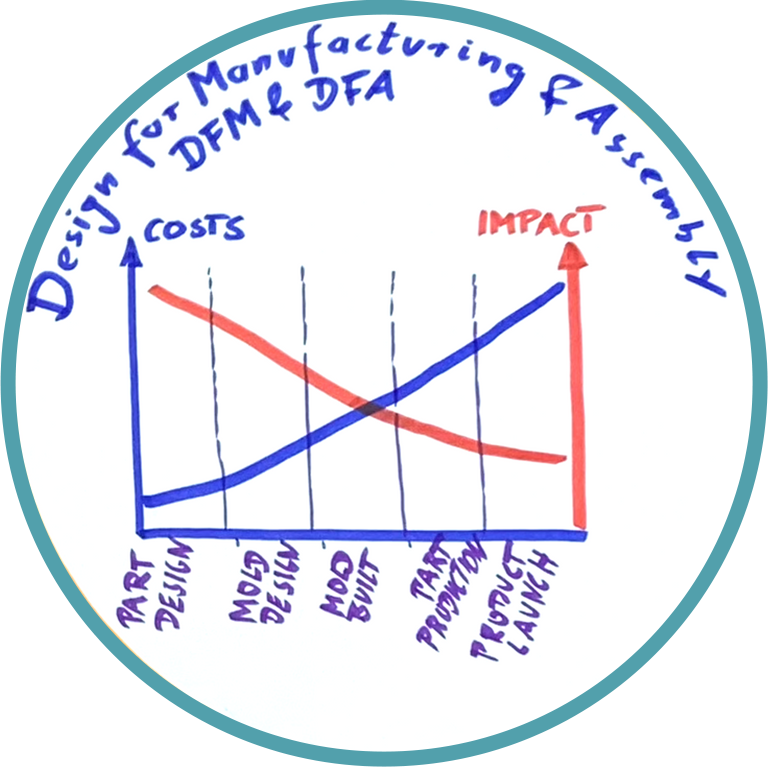

- Product and process development for medium-priced products in in-house production (instead of external production)

- Optimisation of order picking and dispatch

Success factors

In addition to a clear definition of objectives and the use of suitable project management methods, good stakeholder management and excellent communication (within the project team and in the company as a whole) were particularly important success factors.